1、法規(guī)指南:

1.1 NMPA:(原文部分引用)

二����、亞硝胺類雜質(zhì)產(chǎn)生的原因

根據(jù)目前所知����,亞硝胺類雜質(zhì)有多種產(chǎn)生原因,如工藝產(chǎn)生����、降解途徑和污染引入等����。具體來講,亞硝胺類雜質(zhì)可能通過以下途徑引入:

(一)由工藝引入亞硝胺類雜質(zhì)的風(fēng)險

目前所知����,NDMA����、NDEA雜質(zhì)可能通過亞硝化機(jī)理生成����。即在一定條件下����,胺類化合物尤其是仲胺����,與亞硝酸鈉(NaNO2)或其他亞硝化試劑反應(yīng)產(chǎn)生亞硝胺類雜質(zhì)����。在同一工藝步驟中使用了能引入仲胺和亞硝化試劑的物料(包括起始物料����、溶劑、試劑����、催化劑����、中間體等)����,有較高的風(fēng)險引入亞硝胺類雜質(zhì)����;即使在不同的工藝步驟中分別使用能引入仲胺和亞硝化試劑的物料,也可能會產(chǎn)生亞硝胺類雜質(zhì)����。除物料本身帶有仲胺結(jié)構(gòu)外����,仲胺可能的來源有:伯胺����、叔胺及季銨可能引入仲胺雜質(zhì)����;酰胺類溶劑(如N,N-二甲基甲酰胺����、N-甲基吡咯烷酮等)在適宜的條件下(如:酸性,高溫等)可能產(chǎn)生仲胺����。

亞硝化試劑可能引入來源有:亞硝酸鹽����、亞硝酸酯����、亞硝酸����、由亞硝酸鹽制備的物質(zhì)(如:疊氮化鈉等)����,胺類化合物的氧化等����。

(二)由污染引入的風(fēng)險

原料藥生產(chǎn)過程中使用了被亞硝胺類雜質(zhì)污染的物料(起始物料、中間體����、溶劑����、試劑����、催化劑等)可能帶來亞硝胺類雜質(zhì)的風(fēng)險����。

使用回收的物料亦有引入亞硝胺類雜質(zhì)的風(fēng)險。已發(fā)現(xiàn)的回收物料被亞硝胺污染的實例包括鄰二甲苯����、氯化三丁基錫(用作疊氮化三丁基錫的來源)����、N����,N-二甲基甲酰胺(DMF)����。在同一生產(chǎn)線生產(chǎn)不同的品種����,交叉污染也可能成為引入亞硝胺類雜質(zhì)的潛在原因����。

(三)降解產(chǎn)生風(fēng)險

某些藥物本身會降解產(chǎn)生亞硝胺類雜質(zhì),如雷尼替丁在高溫下會產(chǎn)生亞硝胺類雜質(zhì)����。

1.2 EMA(17 April 2025 EMA/409815/2020 Rev.22)

Use of nitrite salts and esters (e.g. NaNO2, alkyl nitrites), or other nitrosating agents (e.g. nitroso halides, nitrosonium salts, nitrogen oxides, nitro alkanes, halogenated nitro alkanes, Fremy’s salt, nitroso sulfonamides) in the presence of secondary or tertiary amines within the same or different steps of the manufacturing process. Sources for secondary or tertiary amines can also be starting materials, intermediates, reagents, solvents (e.g. DMF, DMAc and NMP) and catalysts, which contain amine functionality, amine impurities (e.g. quaternary ammonium salts) or which are susceptible to degradation to reveal amines.

生產(chǎn)工藝中在二級胺或三級胺存在的相同或不同的步驟中����,使用亞硝酸鹽和亞硝酸酯(NaNO2����,RONO)或者其他亞硝化試劑(NOCl����,NO2BF4, N2O3, N2O4, MeNO2, 鹵代硝基甲烷����,弗氏鹽����,亞硝基磺酰胺)����。

二級或三級胺的來源可以是含有胺官能團(tuán)的,或者含有胺雜質(zhì)(如季銨鹽中)����,或者容易降解釋放出胺的起始物料����,中間體����,試劑����,溶劑(DMF,DMAc,NMP)和催化劑����。

Nitrite formation by oxidation of hydroxylamine or nitrite release from nitro-aromatic precursors (e.g. by fluoro de-nitration), in the presence of secondary or tertiary amines within the same or different steps of the manufacturing process

在生產(chǎn)過程中����,二級胺和三級胺存在的相同或不同步驟,通過羥胺氧化形成亞硝酸鹽����,或從硝基芳香族前體中釋放亞硝酸鹽(例如通過氟取代硝基過程)

Use of disinfected water (chlorination, chloro-amination, ozonisation) in the presence of secondary or tertiary amines within the same or different steps of the manufacturing process

在生產(chǎn)過程中����,二級胺和三級胺存在的相同或不同步驟使用消毒水(氯化����、氯胺化����、臭氧化)

Oxidation of hydrazines, hydrazides and hydrazones by hypochlorite, air, oxygen, ozone and peroxides in the manufacturing process or during storage.

在生產(chǎn)過程中或儲存期間,肼類����、酰肼類和腙類化合物被次氯酸鹽����、空氣、氧氣����、臭氧及過氧化物氧化的情況

Use of contaminated raw, recovered or recycled materials (e.g. solvents, reagents and catalysts) in the API manufacturing process.在原料藥生產(chǎn)過程中使用受污染的原始����、回收或再生材料(例如溶劑、試劑和催化劑)Use of contaminated starting materials and intermediates supplied by vendors who use processes or raw materials which may contain residual nitrosamines or nitrosating agents

使用受污染的起始物料和中間體����,這些物料由供應(yīng)商提供,而供應(yīng)商所采用的工藝或原材料可能含有殘留的亞硝胺或亞硝化試劑����。

Carry-over of nitrosamines deliberately generated (e.g. as starting materials or intermediates) during the manufacturing process

在生產(chǎn)過程中故意生成的亞硝胺(例如,作為起始原料或中間體)的殘留����。

Cross-contamination due to different processes being run successively on the same manufacturing line在相同的生產(chǎn)線上運行不同的工藝導(dǎo)致的交叉污染����。

Carry-over of impurities between process steps due to operator-related errors or insufficiently detailed batch records such as inadequate phase separations during work-up procedures.

由于操作員相關(guān)錯誤或批次記錄不夠詳細(xì)(例如在處理過程中相分離不充分),導(dǎo)致雜質(zhì)在各工藝步驟之間殘留����。

Use of contaminated recovered or recycled materials (e.g. solvents, reagents and catalysts) where the recovery is outsourced to third parties who are not aware of the content of the materials they are processing. Recovery processes carried out in non-dedicated equipment should also be considered.

使用受污染的回收材料(例如溶劑、試劑和催化劑)����,而這些材料的回收工作外包給了第三方,而第三方并不清楚他們所處理材料的成分����。在非專用設(shè)備中進(jìn)行的回收過程也應(yīng)予以考慮。

1.3 FDA(Control of Nitrosamine Impurities in Human Drugs Guidance for Industry. September 2024,R2)

Formation of nitrosamines is possible in the presence of secondary, tertiary, or quaternary amines20 and nitrite salts21 under acidic reaction conditions. Under these conditions, nitrite salts may form nitrous acid, which can react with an amine to form a nitrosamine.

在酸性反應(yīng)條件下����,若存在仲胺、叔胺或季胺以及亞硝酸鹽����,就有可能形成亞硝胺����。在這些條件下����,亞硝酸鹽可能會生成亞硝酸����,而亞硝酸可與胺發(fā)生反應(yīng)形成亞硝胺����。

There is a greater risk of nitrosamine formation if nitrous acid is used to quench residual azide (a reagent commonly used in tetrazole ring formation or introduction of azide functional group into a molecule) in the presence of precursor amines.

在胺前體存在下����,如果用亞硝酸淬滅殘留疊氮(一種用于四氮唑環(huán)合成或者分子中引入疊氮官能團(tuán)的試劑)會有更大的風(fēng)險形成亞硝胺����。

Nitrites used as reagents in one step can carry over into subsequent steps, despite purification operations, and react with amines to generate nitrosamine impurities. Therefore, whenever nitrite salts are present, carryover into subsequent steps cannot be ruled out. In general, processes that use nitrites in the presence of secondary, tertiary, or quaternary amines are at risk of generating nitrosamine impurities.

一步反應(yīng)中用作試劑的亞硝酸鹽,盡管經(jīng)過純化操作����,仍可能帶入后續(xù)步驟����,并與胺類反應(yīng)生成亞硝胺雜質(zhì)����。因此����,只要存在亞硝酸鹽����,就不能排除其帶入后續(xù)步驟的可能性����。一般來說����,在仲胺����、叔胺或季胺存在的情況下使用亞硝酸鹽的工藝����,存在生成亞硝胺雜質(zhì)的風(fēng)險。

Amines may be present in a manufacturing process for a variety of reasons. The API (or API degradants), intermediates, or API raw materials22 may contain secondary or tertiary amine functional groups. Tertiary and quaternary amines may also be added intentionally as reagents or catalysts. All of these types of amines can react with nitrous acid or other nitrosating agents to form nitrosamines

在制造過程中����,胺類物質(zhì)的存在可能有多種原因。原料藥(或原料藥降解產(chǎn)物)����、中間體或原料藥原料可能含有仲胺或叔胺官能團(tuán)����。叔胺和季胺也可能被有意添加作為試劑或催化劑。所有這些類型的胺都能與亞硝酸或其他亞硝化劑反應(yīng)生成亞硝胺����。

Amide solvents, which are susceptible to degradation under certain reaction conditions, are another source of secondary amines.

酰胺溶劑����,在特定反應(yīng)條件下����,易發(fā)生降解,是二級胺的另一來源

Secondary amines could also be present as impurities in amide solvents. For example, dimethylamine, which can react with nitrous acid to form NDMA, may exist as an impurity in N,N-dimethylformamide.

二級胺可能作為雜質(zhì)在酰胺溶劑中存在,如DMF中的二甲胺����。

Tertiary and quaternary amines used as reagents in the synthesis of APIs may contain other amine impurities. Tertiary amines, such as triethylamine, have been shown to contain low levels of other secondary amines (such as dipropylamine and isopropylethylamine). Secondary and tertiary amines may be present as impurities or degradants formed by dealkylation of quaternary amines. For example, a common phase-transfer catalyst, tetrabutylammonium bromide, may contain tributyl- and dibutylamine impurities. The amine impurity level that may lead to nitrosamine impurities in the API is process-dependent and should be determined by each API manufacturer.

在原料藥合成中用作試劑的叔胺和季胺可能含有其他胺類雜質(zhì)����。叔胺(如三乙胺)已被證實含有少量其他仲胺(如二丙胺和異丙基乙胺)����。仲胺和叔胺可能作為雜質(zhì)存在����,也可能是季胺脫烷基化形成的降解產(chǎn)物����。例如����,一種常見的相轉(zhuǎn)移催化劑-四丁基溴化銨,可能含有三丁胺和二丁胺雜質(zhì)����?���?赡軐?dǎo)致原料藥中產(chǎn)生亞硝胺雜質(zhì)的胺類雜質(zhì)水平取決于工藝����,應(yīng)由各原料藥生產(chǎn)商確定。

Vendor-Sourced Raw Materials Containing Nitrosamine Impurities

來源于供應(yīng)商的原料含有亞硝胺雜質(zhì):

Nitrosamines have been found in fresh solvents (ortho-xylene, toluene, and methylene chloride) when impurities were carried over during transfer between storage vessels used in the shipment of solvents.

在用于溶劑運輸?shù)膬Υ嫒萜髦g轉(zhuǎn)移溶劑時����,若雜質(zhì)被帶入����,新鮮溶劑(鄰二甲苯����、甲苯和二氯甲烷)中就會發(fā)現(xiàn)亞硝胺����。

Sodium nitrite is a known impurity in some starting materials (such as sodium azide) and may be present and react with amines under acidic conditions to form nitrosamines. Nitrate-containing raw materials, such as potassium nitrate, may contain nitrite impurities. The amount of nitrite impurity that can be tolerated is process-dependent and should be determined by each API manufacturer.

亞硝酸鈉是某些起始原料(如疊氮化鈉)中已知的雜質(zhì)����,在酸性條件下可能存在并與胺類反應(yīng)生成亞硝胺����。含硝酸鹽的原料(如硝酸鉀)可能含有亞硝酸鹽雜質(zhì)。可耐受的亞硝酸鹽雜質(zhì)含量取決于工藝,應(yīng)由各原料藥生產(chǎn)商確定����。

Secondary or tertiary amines have been reported as impurities in some raw materials (see details in section III.B.2.) and in fresh solvents such as toluene.

據(jù)報道����,仲胺或叔胺在一些原材料中(詳見第 III.B.2 節(jié))以及甲苯等新鮮溶劑中會作為雜質(zhì)存在����。

API starting materials and API intermediates may be at risk through cross-contamination at the manufacturing site if these materials are manufactured where nitrosamine impurities can carry over from other processes.

如果原料藥起始物料和原料藥中間體是在可能從其他工藝中帶入亞硝胺雜質(zhì)的場所生產(chǎn)的����,那么在生產(chǎn)現(xiàn)場,這些物料可能會面臨交叉污染的風(fēng)險����。

Recovered Solvents, Reagents, and Catalysts as Sources of Nitrosamine Impurities回收溶劑,試劑����,催化劑的使用是亞硝胺雜質(zhì)的潛在來源。

Recovered materials such as solvents, reagents, and catalysts may pose a risk of nitrosamine impurities due to the presence of residual amines (such as trimethylamine or diisopropylethylamine). If the recovery process involves a quenching step (i.e., nitrous acid used to decompose residual azide), nitrosamines could form during solvent recovery. These nitrosamines may be entrained if they have boiling points or solubility properties similar to the recovered materials, depending on how recovery and subsequent purification takes place (e.g., aqueous washes or distillation). This further increases the risk of nitrosamines in material recovery. For 8 Contains Nonbinding Recommendations these reasons, some drug products using APIs manufactured by certain “low” risk processes23 were found to contain nitrosamine impurities. The Agency has observed the following due to this root cause:

回收的材料(如溶劑����、試劑和催化劑)可能因存在殘留胺(如三甲胺或二異丙基乙胺)而有亞硝胺雜質(zhì)風(fēng)險����。如果回收過程包含淬滅步驟(即使用亞硝酸分解殘留的疊氮化物)����,那么在溶劑回收過程中可能會形成亞硝胺����。如果這些亞硝胺的沸點或溶解度特性與回收材料相似����,它們可能會被夾帶����,這取決于回收及后續(xù)純化的方式(例如水洗或蒸餾)����。這進(jìn)一步增加了材料回收過程中出現(xiàn)亞硝胺的風(fēng)險����。出于這些原因����,一些使用通過某些“低” 風(fēng)險工藝生產(chǎn)的原料藥的藥品被發(fā)現(xiàn)含有亞硝胺雜質(zhì)����。基于這一根源����,該機(jī)構(gòu)觀察到以下情況:

• A manufacturing site may produce the same API by more than one synthetic process that uses common solvents. If any of those synthetic processes produces nitrosamines or contains precursor amines, the solvents sent for recovery are at risk. The use of recovered solvents that are commingled from different processes or across manufacturing lines without control and monitoring can introduce nitrosamine impurities. If a recovered solvent with nitrosamine impurities is used to manufacture an API, the API will contain the impurities even if the synthetic route is not normally susceptible to nitrosamine formation.

一個生產(chǎn)場地可能通過多種使用通用溶劑的合成工藝生產(chǎn)同一種原料藥����。如果這些合成工藝中的任何一種會產(chǎn)生亞硝胺或含有前體胺����,那么送去回收的溶劑就會面臨風(fēng)險����。在沒有控制和監(jiān)測的情況下����,使用從不同工藝或不同生產(chǎn)線混合回收的溶劑,可能會引入亞硝胺雜質(zhì)����。如果使用含有亞硝胺雜質(zhì)的回收溶劑來生產(chǎn)原料藥,那么即使該合成路線通常不易形成亞硝胺����,原料藥中也會含有這些雜質(zhì)����。

• Recovery of raw materials (e.g., solvents, reagents, and catalysts) is often outsourced to third-party contractors. Process outsourcing can pose a risk if the third-party recovery facility does not receive enough specific information on the contents of the materials it is processing and relies solely on routine recovery processes.

原材料(例如溶劑����、試劑和催化劑)的回收工作通常外包給第三方承包商����。如果第三方回收設(shè)施沒有收到關(guān)于其處理的材料成分的足夠具體信息,而僅依賴常規(guī)回收流程����,那么流程外包就可能帶來風(fēng)險����。

• Raw materials can contain nitrosamine impurities if adequate cleaning of equipment between customers, or between different materials, is not carried out or is not validated as capable of removing each impurity of concern. It was reported that nitrosamine impurities were introduced into recycled ortho-xylene and toluene due to inadequate cleaning and use of shared storage equipment between different customers. Inadequate and unvalidated cleaning procedures can also lead to cross-contamination if precautions to avoid nitrosamines are not in place before materials from different customers are combined for recovery. For example, nitrosamine impurities were introduced into lots of the catalyst tri N-butyltin chloride (used as a source of tri-N-butyltin azide) at a third-party contractor facility due to the combining of catalyst lots from multiple customers.

如果在客戶之間����、不同物料之間對設(shè)備的清潔不充分����,或者未驗證清潔是否能夠去除每種相關(guān)雜質(zhì)����,那么原材料可能會含有亞硝胺類雜質(zhì)。據(jù)報道����,由于清潔不充分以及不同客戶共用存儲設(shè)備����,亞硝胺類雜質(zhì)被引入到回收的鄰二甲苯和甲苯中����。如果在將不同客戶的物料合并回收之前����,沒有采取避免亞硝胺產(chǎn)生的預(yù)防措施����,那么不充分且未經(jīng)驗證的清潔程序也可能導(dǎo)致交叉污染����。例如����,在一家第三方承包商的工廠里����,由于將多個客戶的催化劑批次進(jìn)行合并����,亞硝胺類雜質(zhì)被引入到數(shù)批三正丁基氯化錫催化劑(用作三正丁基疊氮化錫的來源)中����。

Quenching Process as a Source of Nitrosamine Impurities

淬滅工藝-亞硝胺的來源

There is a risk of nitrosamine formation when a quenching step is conducted directly in the main reaction mixture (i.e., when nitrous acid is added to the reaction mixture to decompose residual azide). This allows nitrous acid to come into direct contact with residual amines in the raw materials used in the manufacturing process. The nitrosamine impurities could be carried to the subsequent steps if adequate removal or purification operations are not in place, or if the operations are not optimized for removing specific impurities of concern. These impurities can enter the downstream process once they are introduced. Even if the quenching process is conducted outside of the main reaction mixture , there is a risk if recovered materials containing nitrosamine impurities are introduced into the main process.

當(dāng)淬滅步驟直接在主反應(yīng)混合物中進(jìn)行時(即向反應(yīng)混合物中加入亞硝酸以分解殘留的疊氮化物時)����,存在亞硝胺形成的風(fēng)險����。這會使亞硝酸與制造過程中使用的原材料中的殘留胺直接接觸����。如果沒有適當(dāng)?shù)娜コ蚣兓僮鳎蛘哌@些操作未針對去除特定的目標(biāo)雜質(zhì)進(jìn)行優(yōu)化����,亞硝胺雜質(zhì)可能會被帶入后續(xù)步驟����。這些雜質(zhì)一旦引入����,就會進(jìn)入下游工藝����。即使淬滅過程在主反應(yīng)混合物之外進(jìn)行����,如果將含有亞硝胺雜質(zhì)的回收物料引入主工藝����,也會存在風(fēng)險����。

Lack of Process Optimization and Control缺少工藝優(yōu)化和控制Another potential source of formation of nitrosamine impurities is lack of optimization of the manufacturing process for APIs when reaction conditions such as temperature, pH, or the sequence of adding reagents, intermediates, or solvents are inappropriate or poorly controlled. FDA has seen instances in which reaction conditions varied widely between batches and even between different processing equipment in the same facility for the same API. Additionally, certain manufacturing processes using forced air, such as fluid bed drying at elevated temperature and jet milling, can create favorable conditions for nitrosamine formation in at-risk APIs when nitrogen oxides in the air react with the APIs. The multiple root causes of nitrosamine impurities listed above can occur within the same API process. Therefore, multiple strategies may be necessary to identify all potential sources of nitrosamine formation. Typical routine tests (e.g., high performance liquid chromatography) for API purity, identity, and known impurities are unlikely to detect the presence of nitrosamine impurities. Further, each failure mode could result in different nitrosamines in different amounts across batches from the same process and the same API manufacturer, with nitrosamine impurities detected in some batches but not all.

亞硝胺雜質(zhì)形成的另一個潛在來源是原料藥生產(chǎn)工藝缺乏優(yōu)化,例如溫度����、pH 值或加入試劑����、中間體����、溶劑的順序等反應(yīng)條件不合適或控制不當(dāng)����。美國食品藥品監(jiān)督管理局(FDA)已發(fā)現(xiàn)����,對于同一種原料藥不同批次之間,甚至同一設(shè)施中不同加工設(shè)備之間的反應(yīng)條件差異很大的情況����。此外����,某些使用壓縮空氣的生產(chǎn)工藝����,如高溫流化床干燥和氣流粉碎����,當(dāng)空氣中的氮氧化物與原料藥發(fā)生反應(yīng)時����,可能會為存在風(fēng)險的原料藥中形成亞硝胺創(chuàng)造有利條件。上述列出的亞硝胺雜質(zhì)的多種根本原因可能在同一原料藥工藝中出現(xiàn)����。因此����,可能需要多種策略來識別亞硝胺形成的所有潛在來源����。用于檢測原料藥純度、鑒別以及已知雜質(zhì)的典型常規(guī)測試(例如高效液相色譜法)不太可能檢測出亞硝胺雜質(zhì)的存在。此外����,每種失效模式都可能導(dǎo)致同一工藝和同一原料藥生產(chǎn)商生產(chǎn)的不同批次中出現(xiàn)不同種類和不同含量的亞硝胺����,有些批次中檢測出亞硝胺雜質(zhì)����,而有些批次則未檢測出����。

2����、技術(shù)文獻(xiàn)

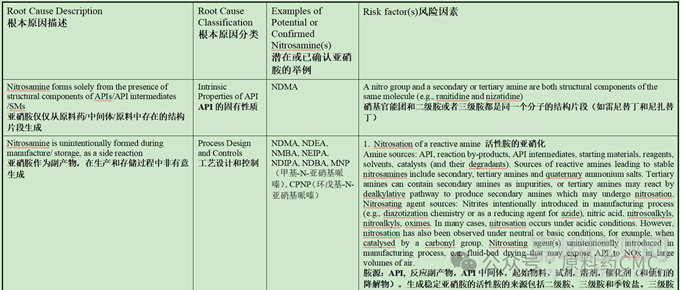

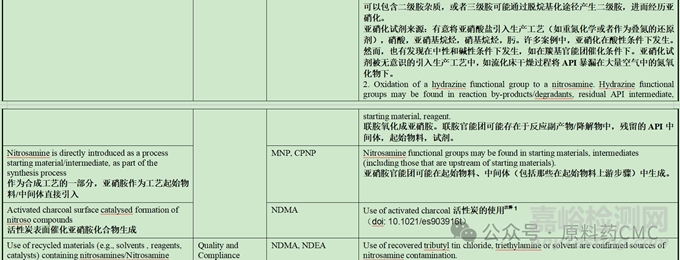

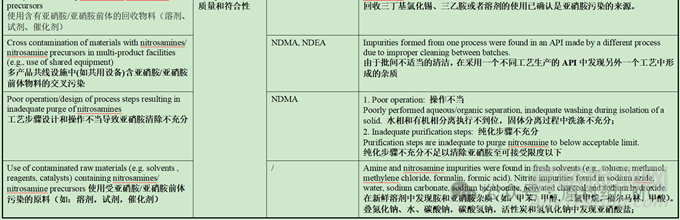

Regulatory Experiences with Root Causes and Risk Factors for Nitrosamine Impurities in Pharmaceuticals

該文章由加拿大衛(wèi)生部����,美國FDA����,新加坡衛(wèi)生科學(xué)局,巴西國家衛(wèi)生監(jiān)督局����,EMA阿姆斯特丹,德國聯(lián)邦藥品與醫(yī)療器械研究所工作人員聯(lián)合發(fā)表����。

Root Causes and Risk Factors from Active Pharmaceutical Ingredients (APIs)

原料藥中形成亞硝胺的根本原因和風(fēng)險因素

注釋1:研究表明:活性炭可以在水中催化亞硝酸鹽和二甲胺形成亞硝胺����。但當(dāng)水中亞硝酸鹽的含量低于0.023mg/L時����,則不存在該風(fēng)險����。另外,該研究結(jié)果給出,水溶液中生成亞硝胺的量占總體的10%����,90%的亞硝胺是在后續(xù)干燥過程中產(chǎn)生。反應(yīng)條件研究結(jié)果表明����,在活性炭催化的亞硝胺形成過程中,仲胺是亞硝胺的前體����,且胺的濃度和結(jié)構(gòu)對反應(yīng)有顯著影響。(與其疏水性可能相關(guān)����,更容易被富集到活性炭上����,濃度提高)����。隨著pH值的升高亞硝胺的生成量增加����,與亞硝胺在酸性條件下的反應(yīng)條件相悖,可能存在其他因素����,最終推測在氧氣的存在下����,活性炭表面能夠催化氧化吸附的仲胺和亞硝酸鹽形成亞硝胺����。

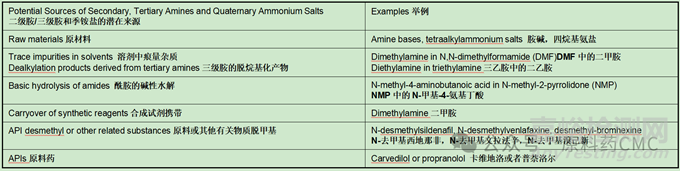

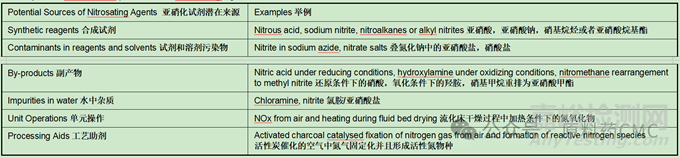

Examples of nitrosamine precursors - amines.亞硝胺前體-胺

Examples of nitrosamine precursors - nitrosating agents.亞硝胺前體-亞硝化試劑

3、參考文獻(xiàn)

Regulatory Experiences with Root Causes and Risk Factors for Nitrosamine Impurities in Pharmaceuticals.https://doi.org/10.1016/j.xphs.2022.12.022